När naturen blir en riskzon: TBE i fokus – trygghet genom vaccin och medvetenhet

Att leva nära naturen är en självklar del av hållbarhet. Det är också en viktig…

Framtidens hållbara konsumentprodukter, när design möter miljökrav

Konsumenternas förväntningar förändras snabbt. Det räcker inte längre att en produkt är funktionell och estetiskt…

Solenergi växer snabbt i Indonesien, Australien och Afrika

Indonesien satsar på ett enormt solkraftsprojekt, Australien upplever en boom i försäljningen av hemmabatterier och…

Energi- och resurseffektivitet i industrins gröna omställning

Industrins omställning till en mer hållbar framtid handlar om mycket mer än att byta ut…

Grön teknik baserad på skogsråvara

Sverige är ett av världens mest skogsrika länder och här finns en enorm potential att…

Så väljer du miljövänligt transfertryck

Att beställa transfertryck online har blivit ett smidigt sätt för företag, föreningar och organisationer att…

Rope Access – Ett Miljövänligt Alternativ till Lyftkran

När det kommer till arbete på hög höjd tänker många automatiskt på lyftkranar, byggställningar eller…

Forskning och innovation i solenergi – nyckeln till hållbar produktutveckling

I takt med att klimatförändringarna intensifieras och energibehovet ökar globalt har intresset för solenergi ökat…

Hållbara Förvaringsskåp – Nyckeln till grönare och säkrare arbetsplatser

I takt med att allt fler företag och organisationer satsar på hållbar utveckling och grön…

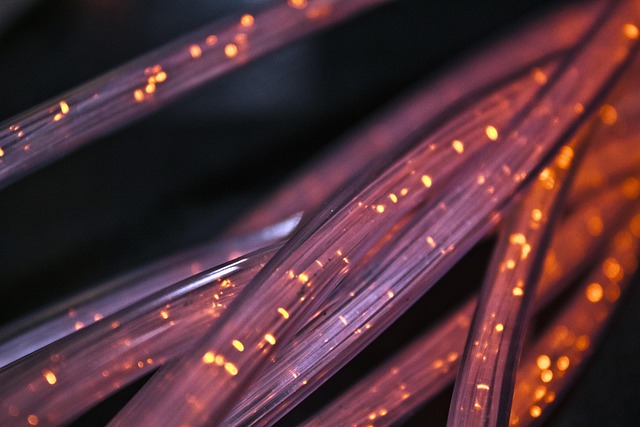

Bredband – En nyckel till klimatsmarta hem och hållbara energival

I takt med att vi bygger framtidens energismarta hem, växer behovet av stabil och snabb…